At NEOTech, we understand that space exploration and satellite technology demand exceptional precision and reliability. Our space-qualified microelectronics manufacturing capabilities are tailored to meet the highest industry standards, ensuring that every component we produce is ready to withstand the unique challenges of the space environment.

NEOTech has been working with NASA partners and other customers in the Space and Satellite market for many decades. We have a history of building microelectronic circuits for OEM’s that extends over 30 years. Our commitment to innovation, quality and service has allowed us to grow over the years to become one of the largest multi-chip module houses in the country.

Our state-of-the-art manufacturing facilities are equipped with cutting-edge technologies specifically designed for the production of microelectronics circuits and assemblies for space applications. Our team specializes in Low-Temperature Co-Fired Ceramic (LTCC) and High-Temperature Co-Fired Ceramic (HTCC) processes, semiconductor packaging, precision wire bonding, and RF and microwave component manufacturing. These specialized capabilities allow us to deliver microelectronics with unmatched reliability, even in extreme conditions.

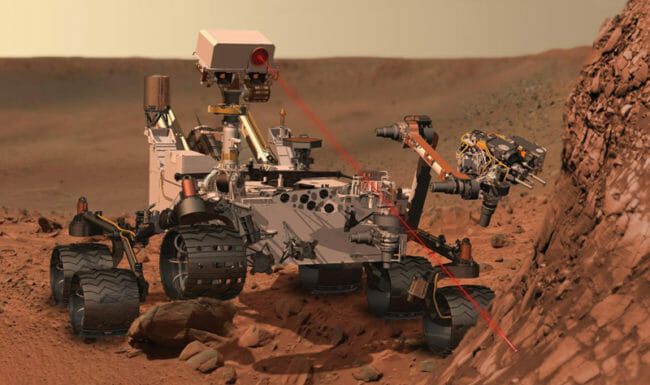

NEOTech’s focus on innovation drives our approach to space-qualified manufacturing. We invest in continuous improvements, from adopting new manufacturing techniques to enhancing existing processes, to ensure we meet the evolving demands of the space industry. Our engineers and technicians are dedicated to advancing space technology and providing solutions that enable our partners to push the boundaries of what’s possible in orbit and beyond.

NEOTech is committed to quality at every stage. We implement strict quality assurance protocols, from initial design and material selection to final assembly and testing, ensuring that each product adheres to stringent space-qualified standards. Our extensive testing processes include thermal cycling, mechanical shock, vibration, and burn-in tests, all conducted in compliance with industry standards like MIL-PRF-38534, MIL-PRF-38535, and NASA’s space environment qualifications. This rigorous approach guarantees the durability and performance required for long-term success in space.

Important Note: NEOTech is one of a few companies qualified by DSSC “womb-to-tomb”.

We have been audited by agencies such as DSSC as well as by DoD primes. Our team has experience managing and maintaining government furnished equipment (GFE).

For over two decades, NEOTech has partnered with leading Aerospace & Defense OEMs to produce complex, mission-critical microelectronics. Our expertise spans across both low and high-volume production, allowing us to meet diverse customer requirements while maintaining exceptional quality and reliability. Whether it’s developing a prototype for a pioneering space mission or scaling production for established programs, NEOTech’s team works closely with customers to ensure flawless execution.

With more than forty years of expertise in high-reliability hybrid and RF technologies, NEOTech has established itself as the largest provider of microelectronics assembly services in North America. We offer a comprehensive array of services encompassing the design, development, and manufacturing of microelectronic assemblies, specializing in microwave electronics and circuits. Our dedicated teams are committed to delivering technical support and advanced testing for microelectronic assemblies, ensuring superior quality and reliability for our customers.