In today’s fast-paced high-tech landscape, delivering high-quality products to customers is more demanding than ever. NEOTech’s Design Services team rises to the challenge every day—bringing innovative engineering solutions to life for some of the world’s most complex and mission-critical products.

Your internal design team knows your product and your customers better than anyone. At NEOTech, we complement that knowledge with deep experience in optimizing complex electronics designs for manufacturability, testability, and long-term reliability. Our Design Services team brings decades of hands-on expertise to evaluate your design from every angle—identifying opportunities to streamline production, enhance efficiency, and reduce risk of defects or failures in the field.

From early-stage concept refinement and design-for-manufacturability (DFM) input to full commercialization studies, we collaborate closely with you to improve design integrity while lowering total production costs. We apply proven engineering principles and lessons learned across Aerospace & Defense, Medical Devices, and High-Tech Industrial markets to help your product perform at its best under real-world conditions.

Once optimized, your design flows seamlessly into our manufacturing operations through a mature and well-audited quality management system. The result: a reliable, repeatable production process that delivers consistent quality from first build to final shipment.

We don’t just provide design recommendations—we integrate with your team, working side-by-side to ensure your product exceeds expectations at every stage of its lifecycle.

For 40-years, we have created an impressive record of working side-by-side with our customers to identify product needs, and then designing quality products that ensure our customers success.

Reduce overall product cost and improve quality with Design for Excellence (DFX) Services. NEOTech provides DFX reviews to identify issues that will impact product cost, quality, and delivery during the design process and makes recommendations for design improvement.

Connecting NEOTech into your design process enables us to help integrate our manufacturing and supply chain expertise early at the design stage. Together, we identify engineering solutions to improve efficiency and quality.

Engineering Design for Manufacturing (DFM) analysis uses proven techniques to review your printed circuit board designs and identify areas of improvement that remove potential failures, reduce fall-out, increase reliability, and ultimately improve manufacturability. Our engineers will review PCBA layer and layer density for opportunities for cost savings through layer count reduction and component consolidation opportunities, as well as general process ability. Post build reviews will be conducted following each production cycle – reviewing process parameters, yield, yield improvements, and production plans creating manufacturing process changes or recommended design changes to enhance yield and decrease product cost.

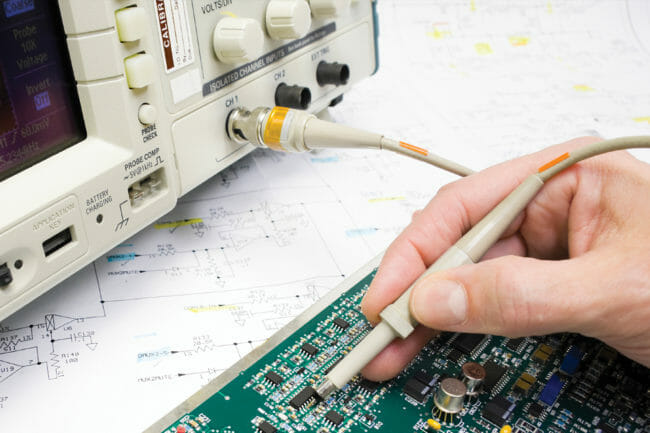

Through a Design for Test (DFT) review, product improvements are made to optimize test access and enhance the test strategy for the best fit of test solutions. In-Circuit Test (ICT) is generally used for the detection of manufacturing process defects at the board level. Typical defects found are wrong component populated, wrong orientation of the component, or missing component. Functional Test is offered to simulate the end functional application and environment of the product. Utilizing the powerful analysis tool Test Wise, our engineers can ascertain if the design has the proper test coverage to fulfill test strategy requirements.

NEOTech works with customers to unlock value through our Value Analysis / Value Engineering (VA/VE) process. VAVE is a continuous improvement strategy in the areas of Design for Manufacturing, Design for Test, Quality Analysis, and Design for Procurement (Supply Chain). NEOTech’s analysis provides the customer a value-add service by optimizing design specifications for component life cycles, supplier risks, and processes among other items. This provides our customers a way to simplify their PCBA design, allowing for lower overall costs and keeping your product competitive in the marketplace.

Our Value Engineering Team — comprised of component, manufacturing, process, and test engineers — address VAVE in:

VAVE Capabilities:

Advances in new technology continue to grow at a staggering pace. NEOTech has experts with in-depth digital design skillsets serving a variety of industries for Digital and FPGA circuit design requirements. Our digital design team is staffed with highly experienced engineers, and recognized as a premier industry leader we strive to provide top-notch engineering solutions to our OEM customers to meet or exceed product requirements.

We have the talent to complete any digital circuit design project. Our team can perform electronic circuit design, as well as mixed signal design for both analog and digital. Plus, digital and FPGA circuit expertise to create field-programmable integrated circuits. We are a leading expert in circuit board designs and electronics solutions.

To serve all your unique design and engineering needs, our team offers a wide range of experience in a variety of design related subject areas:

Engineering requirements for analog circuits become more stringent as high-tech products become more complex. As OEMs continue to develop leading-edge products to meet their customer’s demands utilizing the latest IoT connectivity and advanced user interfaces, we provide the engineering expertise integrated in to our electronics manufacturing best-practices to optimize the product design. NEOTech’s team of Analog engineers are highly experienced in providing innovative solutions for each unique analog circuit design.

The NEOTech team is well-versed in all facets of analog electrical design services including mixed signal, analog circuit, wireless, and RF design services to ensure efficient and comprehensive completion of development programs that improve your new product time-to-market.

Many of NEOTech’s RF design and test core team have history that spans back to AT&T/Bell Labs, and have diverse skills sets to draw upon when serving your company’s product development needs. Coupling this experience with our top-of-the-line engineering tools provides our customers the unique position of selecting the most suitable technology aligned with their unique needs.

Today’s high-tech markets demand products that make life and work easier, are aesthetically pleasing, and deliver the performance expected with quality standards second-to-none. NEOTech utilizes Industrial & Mechanical engineering resources that bring a value-added benefit to your organization by providing innovative solutions for your most complex product challenges.

With several years of high-technology experience developing and engineering a wide-range of products for some of the world’s largest OEM’s, our teams have created quality standards and design techniques to assist you taking a product from concept to delivery to your customers. We give you the tools and the talent to make sure you deliver what you said, when you said.

Our research methodology focuses on discovering and mapping opportunities to be cultivated into executable plans of action.

Our industrial design team knows that ultimately the product needs to be manufactured and keeps this in mind throughout the entire design and development process, while never losing sight of the user’s needs.

Our engineers work closely with our design team to ensure the proper look, feel and functionality of a product is carried throughout the development process. We work to minimize development risk by prioritizing manufacturing needs early on.

In-house 3D printing capability provides quick turn-around which allows for more design iterations in a shorter period-of-time.

Your engineers are experts in your products requirements and the functionality needed for your end users. As such, they may not know best practices for PCBA design to ensure quality and reliable manufacturability. Let NEOTech step in as your trusted PCBA design resource. We have the engineers that are experts at printed circuit board assembly (PCBA) design and layout that interface daily with manufacturing engineers on best practices to ensure a high-quality design layout right from the start.

With experience in FR4, Rigid-Flex, Rogers, and Ceramics, our engineering design services team can ensure quality products to meet your printed circuit board design needs. NEOTech’s engineering expertise includes advanced technology such as microvias, via-in-pad, ultra-fine pitch BGAs and POP. Our engineering design services are supplemented by decades of experience in a variety of areas:

Our design team uses a high-quality engineering toolset that allows them to ensure quality and reliability in each printed circuit board project by using equipment such as, MicroWave Office, Altium, and Mentor, among others. This toolset helps us providing medical, industrial, and mission critical defense applications with inventive solutions and quality service.

Every product, from the simplest PCBA to complex electro-mechanical assemblies, has countless hours of design engineering invested into it; so now is not the time to overlook an integrated test strategy to monitor performance and ensure a zero-defect production run. At NEOTech, we thoroughly analyze your product design and operating requirements to develop a complete test strategy that identifies possible quality issues, then implement testing methodologies to lower production cost, reduce fall-out, and create faster time to market.

Quality is your… and our Top Priority! We make sure with early defect detection. Our test engineering team ensures that quality requirements are met through a wide range of problem-solving techniques. Working side-by-side with the design engineers, our test engineers embed Design for Test thinking in to the product strategy minimizing capital and resource investment for mass manufacturing.

Test Strategy – NEOTech test engineers ensure the appropriate level of testing is performed at the earliest stage in the process to reduce cost through early defect detection.

New and complex electronic products are very difficult to get right in just the first try. Mistakes in placement, orientation, and clearances can arise even though everything seemed in-line through the design process. NEOTech offers Prototyping services integrated in to our transition management process, helping get your product to market faster by correcting any issues that cause delays in manufacturing full production runs.

Your product is vital to your customers, and we make sure the prototyping evaluation gets it right by catching any costly design mistakes or inefficiencies in component selection. NEOTech design engineering teams provide quick turn prototype services to produce early stage samples for engineering evaluation and product functional validation.

Each of our production locations also offer a full suite of New Product Introduction (NPI) services that aids customers in the seamless transition from the design phase into full scale production. These include development of tooling, production and test processes, and quality documentation, as well as early stage and pilot builds for process and market evaluations.

As quickly as new component technology opens the doors to better and more advanced product specifications and development, older components also become obsolete and no longer available. Optimize supply chains and extend product life cycles with NEOTech.

NEOTech leverages our extensive engineering, supply chain and aftermarket services expertise to sustain our customer’s products throughout their lifecycle. By providing customized aftermarket services, we optimize the supply chain and extend product life cycles that enable OEMs to further benefit from the cash generated on their original product development investments. Our history of servicing products in FDA regulated medical markets provides our customers’ solutions that deliver superior customer satisfaction. Our broad range of aftermarket solutions is customized to enable your product’s success long after launch into the marketplace.

Our engineering teams provide decades of expertise at the forefront of technology for a growing number of our OEM customers. We can assist you in finding value enhancing solutions with our engineering design services. We operate as a seamless extension of our customers engineering organizations, adding scale, flexibility and speed to their design process. It is our engineering services strategy to become our customer’s engineering partner at any stage of the design cycle to assist in transforming ideas into production ready products.

At NEOTech we deliver these services with a highly skilled and qualified engineering team with decades of experience designing mission critical aerospace & defense, medical and industrial applications.