In today’s competitive market landscape, enhancing product value is paramount for businesses aiming to stay ahead.

Partnering with an Electronic Manufacturing Services (EMS) provider can be a strategic move towards achieving this goal. An EMS provider brings expertise in design, manufacturing, testing, and logistics, enabling companies to streamline their production processes and deliver high-quality products to the market efficiently. To leverage the full potential of an EMS provider, businesses must focus on key areas such as collaborative design, cost optimization, and supply chain management.

Collaborative design is a cornerstone of maximizing product value with an EMS provider. By involving the EMS partner early in the product development phase, companies can tap into their engineering prowess to optimize designs for manufacturability and cost-effectiveness. This collaborative approach ensures that products are not only innovative but also feasible to produce at scale. Furthermore, close collaboration enables swift iterations, reducing time-to-market and enhancing product competitiveness. By leveraging the EMS provider’s design expertise, businesses can innovate with confidence, knowing that their products are designed for success from the outset.

Your EMS should be more than just a resource… it’s an investment. An investment in a strategic partner with the expert qualification to help you achieve your business goals and satisfy your customer’s needs.

Choosing the right Electronic Manufacturing Services provider is crucial for the success of any product development or manufacturing project.

Whether you’re a startup or an established company, selecting the right EMS partner can significantly impact your product’s quality, time-to-market, and overall cost-effectiveness. Here are some key factors to consider when evaluating EMS providers:

1. Experience and Expertise: Look for an EMS provider with a proven track record and extensive experience in your industry or niche. They should have a deep understanding of your specific requirements, technologies, and compliance standards.

2. Quality Assurance and Certifications: Ensure that the EMS provider follows stringent quality control processes and holds relevant certifications such as ISO 9001, ISO 13485 (for medical devices), AS9100 (for aerospace), or other industry-specific standards. Quality is non-negotiable when it comes to manufacturing high-tech electronic products.

3. Flexibility and Scalability: Your EMS partner should be able to accommodate your current needs while also being flexible enough to scale production as your business grows. This includes flexibility in manufacturing processes, production volumes, and delivery schedules.

4. Cost-effectiveness: While cost shouldn’t be the sole determining factor, it’s essential to find an EMS provider that offers competitive pricing without compromising on quality. Consider factors such as labor costs, material sourcing capabilities, and overhead expenses when evaluating cost-effectiveness.

5. Technology and Innovation: Assess the EMS provider’s technological capabilities and commitment to innovation. Are they equipped with the latest manufacturing equipment and techniques? Do they invest in research and development to stay ahead of industry trends?

6. Supply Chain Management: A robust supply chain is critical for timely delivery and cost control. Evaluate the EMS provider’s supply chain management capabilities, including their relationships with component suppliers, inventory management practices, and risk mitigation strategies.

7. Location and Logistics: Consider the geographical location of the EMS provider in relation to your company’s operations. A closer proximity can facilitate communication, logistics, and potential site visits. Additionally, assess their logistics capabilities to ensure efficient transportation and delivery of finished products.

8. Communication and Collaboration: Effective communication and collaboration are essential for a successful partnership. Evaluate the EMS provider’s responsiveness, transparency, and willingness to collaborate throughout the project lifecycle.

9. Customer Support and After-sales Service: Look for an EMS provider that offers comprehensive customer support and after-sales service. This includes technical assistance, warranty support, and timely resolution of any issues that may arise post-production.

10. Reputation and References: Research the EMS provider’s reputation in the industry and seek references from past or current clients. Testimonials and case studies can provide valuable insights into their performance, reliability, and customer satisfaction.

By carefully considering these factors and conducting thorough due diligence, you can select an EMS provider that aligns with your specific needs and objectives, ultimately contributing to the success of your product development and manufacturing endeavors.

Working with NEOTech has been a transformative experience. Unlike other contract manufacturers, we don’t have to navigate layers of bureaucracy to get answers—we have direct access to their team, and they’re always ready to help. Their technical expertise is outstanding, but what truly sets them apart is their commitment to understanding our product and market. They genuinely care about ensuring the end user gets exactly what they need.

Like any partnership, we’ve faced challenges, but NEOTech consistently steps up, collaborates with us as part of the team, and finds the best solutions. It’s rewarding to work with a company that values collaboration as much as we do. Our experience over the years has been great, and we look forward to continuing this great partnership!

Vice President, Electrification

In the ever-evolving landscape of electronics manufacturing, the pursuit of excellence is not merely a goal but a necessity.

Companies striving for success must continually optimize their processes, reduce costs, enhance product quality, and accelerate time-to-market. In this pursuit, partnering with a Design for Excellence (DFX) EMS expert becomes not just advantageous but imperative. Here’s why:

1. Strategic DFX Implementation: A seasoned DFX EMS expert brings strategic insights into every stage of product development, from design to manufacturing. By integrating Design for Manufacturability (DFM), Design for Testability (DFT), Design for Assembly (DFA), and other DFX principles, they ensure that your product is not just manufacturable but optimized for efficiency and cost-effectiveness throughout its lifecycle.

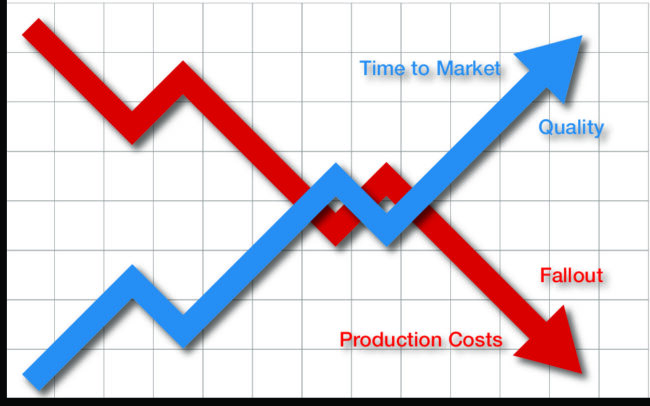

2. Cost Optimization: Cost reduction is a perpetual goal in manufacturing. DFX EMS experts possess the know-how to identify and eliminate potential cost drivers early in the design phase. By optimizing material selection, simplifying assembly processes, and minimizing rework, they help streamline operations and drive down production costs without compromising product quality.

3. Enhanced Product Quality: Quality is non-negotiable in today’s competitive market. By leveraging DFX methodologies, EMS experts enhance product quality by design. They anticipate potential issues, such as component obsolescence or supply chain disruptions, and design robust solutions to mitigate risks, ensuring that your product meets or exceeds industry standards consistently.

4. Accelerated Time-to-Market: In today’s fast-paced market, time-to-market is a critical determinant of success. DFX EMS experts employ agile methodologies and concurrent engineering practices to compress product development cycles. By optimizing design iterations, minimizing prototype iterations, and streamlining manufacturing processes, they help you bring your products to market faster, gaining a competitive edge.

5. Comprehensive Supply Chain Management: The modern electronics supply chain is complex and global. DFX EMS experts offer end-to-end supply chain management solutions, from strategic sourcing and procurement to inventory management and logistics. By forging strategic partnerships with trusted suppliers and implementing robust supply chain strategies, they ensure a seamless flow of materials, minimize lead times, and mitigate supply chain risks.

6. Regulatory Compliance and Sustainability: Navigating regulatory requirements and sustainability standards is paramount in today’s environmentally conscious market. DFX EMS experts stay abreast of evolving regulations and sustainability initiatives, ensuring that your products comply with industry standards and environmental regulations. By adopting eco-friendly manufacturing practices and designing for sustainability, they help you meet regulatory requirements while minimizing environmental impact.

7. Continuous Improvement: Continuous improvement is the cornerstone of operational excellence. DFX EMS experts foster a culture of continuous improvement within your organization by conducting regular design reviews, analyzing manufacturing data, and implementing corrective actions. By identifying areas for optimization and driving process improvements iteratively, they help you stay ahead of the curve in a rapidly evolving industry.

Partnering with a Design for Excellence EMS expert offers a multitude of benefits, ranging from strategic DFX implementation and cost optimization to enhanced product quality, accelerated time-to-market, comprehensive supply chain management, regulatory compliance, sustainability, and continuous improvement. By harnessing their expertise, companies can elevate their electronics manufacturing processes, drive innovation, and gain a competitive edge in today’s dynamic market landscape.

Our organization has been very fortunate to have NEOTech as a member of the team; they are a true partner. Our products are extremely technical and complex, and NEOTech has never shied away from that challenge. Quite the opposite. They always step up to the challenge and working side-by-side with our team, their engineers have helped us enhance multiple aspects of our design. Then, on the manufacturing floor, NEOTech’s team makes sure our product assemblies are completed with great attention to detail and to the highest quality. We are happy to say our product’s success is partially attributed to NEOTech’s commitment to excellence as a contract manufacturer.

Chief Technology Officer

When collaborating with an Electronics Manufacturing Services company, safeguarding your intellectual property (IP) is paramount.

Firstly, it’s essential to establish clear and comprehensive agreements that outline the ownership and protection of your IP throughout the partnership. This includes defining what constitutes confidential information, such as designs, technology, and processes, and implementing measures to ensure its confidentiality. Non-disclosure agreements (NDAs) should be signed by all parties involved, specifying the limitations on the use and disclosure of sensitive information. Additionally, incorporating clauses regarding IP rights into contracts can help clarify ownership and usage rights, providing legal recourse in case of disputes.

Moreover, implementing robust security protocols within the EMS company’s facilities is crucial for protecting your IP. This involves restricting access to sensitive areas and data, implementing surveillance systems, and enforcing strict employee policies regarding the handling of confidential information. Regular audits and inspections can help ensure compliance with security measures and identify any potential vulnerabilities. It’s also beneficial to maintain open communication channels with the EMS company, fostering a collaborative environment where concerns regarding IP protection can be addressed promptly. By proactively addressing these aspects, you can mitigate the risk of IP theft or misuse, safeguarding your innovations and maintaining a competitive edge in the market.

With advancements in technology and increasing demand for innovative devices, EMS providers are poised to play a pivotal role in the production of cutting-edge electronics.

In this dynamic industry, OEMs stand to benefit immensely from partnering with forward-thinking EMS providers. By collaborating with EMS providers equipped with state-of-the-art facilities and expertise, OEMs can leverage economies of scale, access specialized skills, and accelerate time-to-market for their electronic products. Moreover, EMS providers offer OEMs flexibility in scaling production volumes based on market demand, mitigating risks associated with fluctuating consumer preferences and market dynamics. Additionally, EMS providers can provide valuable insights and guidance to OEMs throughout the product lifecycle, from design and prototyping to manufacturing and post-sales support, ensuring seamless integration of electronic components into end-user products.

As the electronics manufacturing landscape continues to evolve, collaboration between EMS providers and OEMs will be crucial for driving innovation and maintaining competitiveness in the global market. By harnessing the capabilities of EMS providers and embracing technological advancements, OEMs can navigate the complexities of the high-technology electronics industry and deliver cutting-edge products that meet the demands of the modern consumer market.

We’ve been partnered with NEOTech for over 5 years, and both organizations have learned much from one another. There have been challenges in seeing eye-to-eye at times, but as with any committed relationship, we’ve worked together to identify obstacles, troubleshoot ideas, and ultimately find solutions that work best for everyone. The NEOTech team has consistently been very accommodating in handling our large matrix organization, staying flexible and agile with input and inquiries from multiple individuals and organizations. Through this effort, NEOTech has worked closely as a member of our team to enhance product designs, resulting in the improvement of quality issues. We’re thrilled to have NEOTech as part of our team.

Global Category Director

In the fast-paced world of technology, the intricacies of electronics manufacturing play a pivotal role in bringing innovative products to life.

At NEOTech, we pride ourselves on being at the forefront of Electronics Manufacturing Services, providing comprehensive solutions that empower businesses to transform their ideas into reality.

What are Electronics Manufacturing Services?

Electronics Manufacturing Services, or EMS, encompass a range of services that streamline the production of electronic components and devices. NEOTech’s EMS offerings cover the entire product lifecycle, from design and prototyping to manufacturing, testing, and aftermarket services.

Key Components of NEOTech’s EMS:

1. Design and Engineering: Our expert team collaborates with clients to conceptualize and design electronic products that meet their specific requirements. From PCB layout to product architecture, we ensure optimal performance and manufacturability.

2. Prototyping and Validation: NEOTech’s state-of-the-art facilities enable rapid prototyping and validation of designs. This phase allows clients to test and refine their concepts before full-scale production, reducing time-to-market and minimizing risks.

3. Precision Manufacturing: Our manufacturing processes adhere to the highest industry standards. NEOTech employs advanced technologies for the production of printed circuit board assemblies (PCBAs), including surface mount technology (SMT) and plated through-hole (PTH) assembly.

4. Testing and Quality Assurance: Rigorous testing procedures are implemented at every stage to guarantee the quality and reliability of the final product. NEOTech is committed to delivering electronics that surpass industry benchmarks.

5. Supply Chain Management: Our comprehensive supply chain solutions ensure a seamless flow of materials and components, optimizing production efficiency and minimizing costs. NEOTech’s global supply chain network facilitates sourcing, procurement, and logistics.

6. Aftermarket Services: NEOTech’s commitment doesn’t end with product delivery. We offer comprehensive aftermarket services, including repair, refurbishment, and end-of-life support, ensuring the longevity of electronic products.

NEOTech’s Electronics Manufacturing Services stand as a testament to our commitment to excellence. Whether you are a smaller organization bringing an innovative concept to market or an established enterprise seeking to optimize production, NEOTech is your trusted partner in the world of electronics manufacturing. Explore the possibilities with us and let your ideas take flight.

Steve Bates, NEOTech Marketing Manager – March 2024

We were immediately struck by NEOTech’s commitment to quality. Their robust quality management system and comprehensive barcode tracking of every component on each PCBA were particularly impressive. As a medical device manufacturer, it’s crucial for us to have the ability to trace any potential defects back to the specific board, ensuring that issues can be resolved even before shipment. Additionally, NEOTech’s engineers conducted a thorough DFX analysis on several of our PCBAs, providing clear recommendations for design modifications to enhance manufacturability. They also identified BOM components nearing end-of-life and suggested valid replacements, ultimately helping us reduce costs.