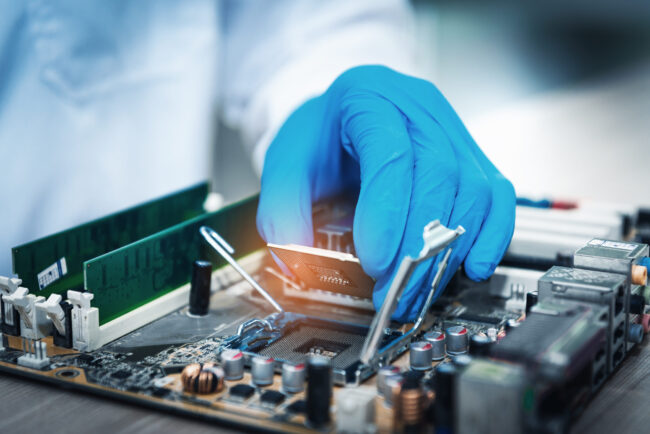

NEOTech is the clear-choice as your partner for high-technology Medical Device Manufacturing. We’re your trusted resource with decades of ISO 13485 experience and expertise working with several leading medical device OEMs on the most advanced medical technologies available.

Your number one goal is to provide the healthcare industry with your innovative medical product that enhances patient treatment and care. We’re here to work with you as an extension of your team to make sure your product is designed and engineered to meet the stringent requirements for medical equipment electronics manufacturing. Together as a team, our organizations will collaborate on meeting and beating industry requirements, identifying innovative solutions to challenging product features, and get your device to market faster with less risk.

Our top priority is to provide total commitment and dedication to the development and manufacturing of your medical devices – because with Life on the line and ZERO tolerance for failure, you must have a trusted partner you can depend on to deliver reliable life-saving products.

Caregivers and patients depend on your products every day to perform perfectly ensuring lives are protected and saved. At-home monitoring systems, life-saving AEDs, electronic thermometers, and large hospital capital equipment systems are among the advanced medical technologies NEOTech has manufactured for several years for our customers. Our Quality Management System has been developed and enhanced over many years to ensure only the highest-reliability products leave our facilities. Plus, with our focus on continuous improvements and employee empowerment, we eliminate inefficiencies, improve production cycle-times, and reduce your overall landed costs.

Working as an extension of your team, NEOTech makes your product vision a reality for end-to-end product development and electronics manufacturing of complex medical equipment.

NEOTech’s Medical design and manufacturing team is focused on building products that improve the patient experience by creating solutions optimized for your medical device. While closely collaborating with your team, we’re able to provide a comprehensive set of services tailored to create a custom solution for your low-to-medium volume, high-mix medical equipment. NEOTech has multiple locations certified to ISO 13485.

Healthcare products demand perfection – for both the complexity of healthcare technologies and the lives that depend on them. It takes more than an average electronic manufacturing services provider to support the needs of medical equipment manufacturing; it requires a special dedication to quality through the entire product value-stream. Our unique combination of processes, systems, people, and tools maximize your product’s quality to ensure you’re able to compete with more agility, keeping your products ahead of the competition. As one of the industry’s top medical device manufacturers, we have the expertise to provide the highest level of service for our customers.

Selecting the right Electronics Manufacturing Services (EMS) provider is a critical decision for OEMs developing medical equipment, as it directly impacts product quality, compliance, and overall success.

Selecting the right Electronics Manufacturing Services (EMS) provider is a critical decision for OEMs developing medical equipment, as it directly impacts product quality, compliance, and overall success.Navigating the complexities of PCBA manufacturing and circuit card assembly requires specialized expertise, advanced equipment, and stringent quality controls—areas where NEOTech excels. However, before choosing an EMS partner, it’s essential to understand the key factors that influence manufacturing efficiency, cost-effectiveness, and long-term reliability. That’s why we’ve developed a comprehensive guide to EMS, equipping OEMs with the knowledge needed to make informed decisions. Read the guide now to gain critical insights into selecting the right partner and ensuring a seamless transition from design to production.

We were immediately struck by NEOTech’s commitment to quality. Their robust quality management system and comprehensive barcode tracking of every component on each PCBA were particularly impressive. As a medical device manufacturer, it’s crucial for us to have the ability to trace any potential defects back to the specific board, ensuring that issues can be resolved even before shipment. Additionally, NEOTech’s engineers conducted a thorough DFX analysis on several of our PCBAs, providing clear recommendations for design modifications to enhance manufacturability. They also identified BOM components nearing end-of-life and suggested valid replacements, ultimately helping us reduce costs.

NEOTech’s medical experience includes building high-reliability medical microelectronics used in human implantable applications. Size and weight are critical, especially when it comes to implantable medical devices, and NEOTech has particular expertise building medical microelectronics and chip-on-board (COB) assemblies that deliver high performance at a minimum of size and weight.

The quality and reliability of such micro-medical devices is crucial. Considering this, we make great efforts and take great pride in our process controls, quality, and medical device design. We’ve addressed these unique circumstances by developing strict processes and focused capabilities. We work hard to earn your trust and provide high-quality contract medical device manufacturing for both out-of-body and implantable devices.

Offshore manufacturing strategies are collapsing under the weight of rising tariffs, unpredictable logistics, and quality control challenges. NEOTech offers a smarter path forward—with trusted U.S. and Mexico-based electronics manufacturing services built for resilience, agility, and excellence.